Fiberlogy ASA is often referred to as the successor to ABS. Due to its exceptional resistance to UV radiation, high temperatures (up to 94°C) and humidity, it is perfect for printing models exposed to long-term weather conditions. At the same time, the material is very durable and simple to print.

Because ASA is characterized by low shrinkage, high adhesion and less emission of unpleasant odors compared to ABS, it can be used in printers that are not fitted with a heated chamber.

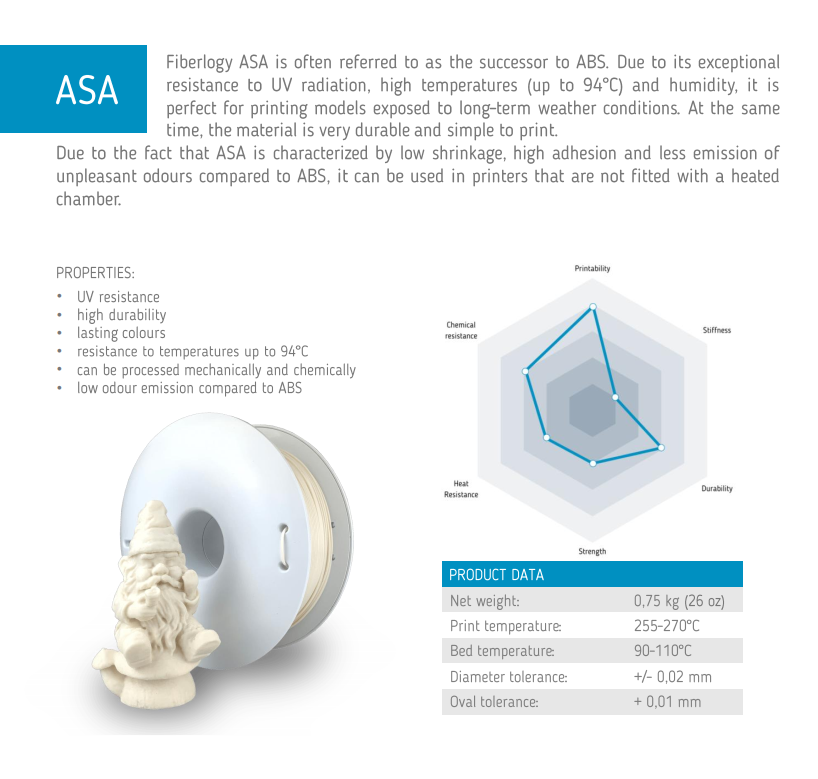

Properties:

- UV Resistant.

- High Durability

- Colors will not fade over time.

- Can be smoothed chemically.

- Low odor emission during printing.

- Printing temperature: 255°C — 270°C

- Bed temperature: 90 - 110°C

- Diameter tolerance: +/- 0.02 mm

- Oval tolerance: +0.01 mm

- Net weight: 0.75 kg

See download tab for TDS

Looking for colors that are not listed? Feel free to reach out at sales@aero3ds.com

How to print.

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 255-270°C |

| Bed Temperature | 90-110°C |

| Closed Chamber | not required |

| Fan | 0-25% |

| Flow Rate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 80°C / 4h |

| Notes | When printing without a heated chamber, it is recommended to avoid exposing the model to gusts of wind/drafts. |

Write Review

-

Start Download

MSDS-Original-PA-PC-HT-Flex-Metal