ABS is characterized by its hardness and high impact resistance. It is also resistant to high temperatures and abrasion. Prints made using this filament can be further processed mechanically and chemically (with acetone).

The printed elements can serve as concept models for new products or even as their final versions. ABS can also be used in the production of prototype elements that require greater rigidity.

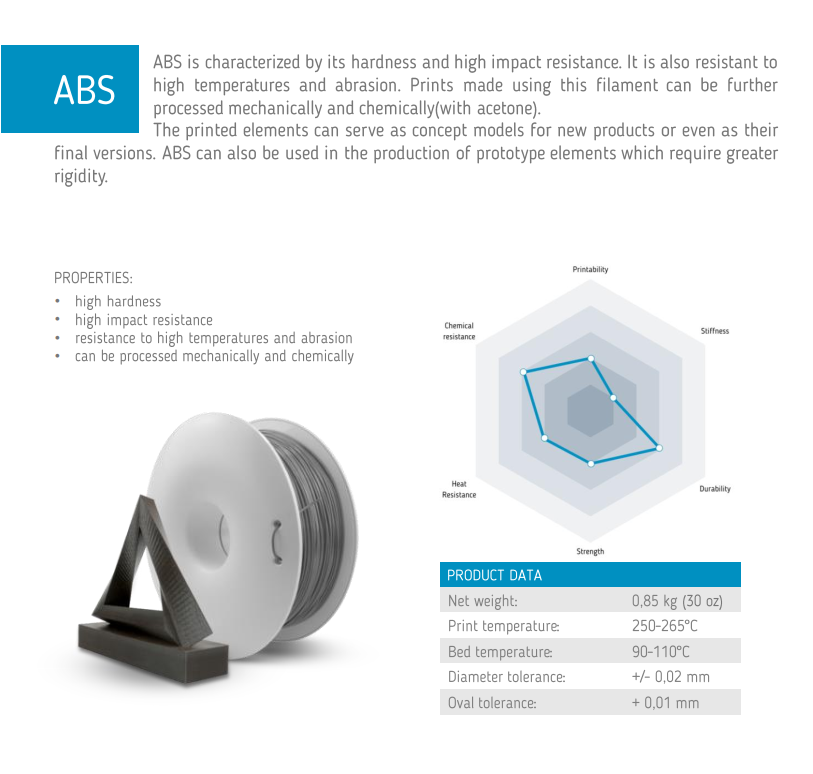

Properties:

- High Hardness.

- High impact Resistance,

- Resistant to high temperatures and abrasions.

- Printing temperature: 250-265°C

- Bed temperature: 90-110°C

- Diameter tolerance: +/- 0.02 mm

- Oval tolerance: +0.01 mm

- Net weight: 0.85 kg

Additional information:

- Can be chemically smoothed.

- Bed heating is required.

- Chamber heating is recommended.

See download tab for TDS.

Looking for colors that are not listed? Feel free to reach out at sales@aero3ds.com

How to print.

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-265°C |

| Bed Temperature | 90-110°C |

| Closed Chamber | recommended |

| Fan | 0-10% |

| Flow Rate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 60°C / 4hrs |

Write Review

-

Start Download

TDS ABS