Fiberlogy

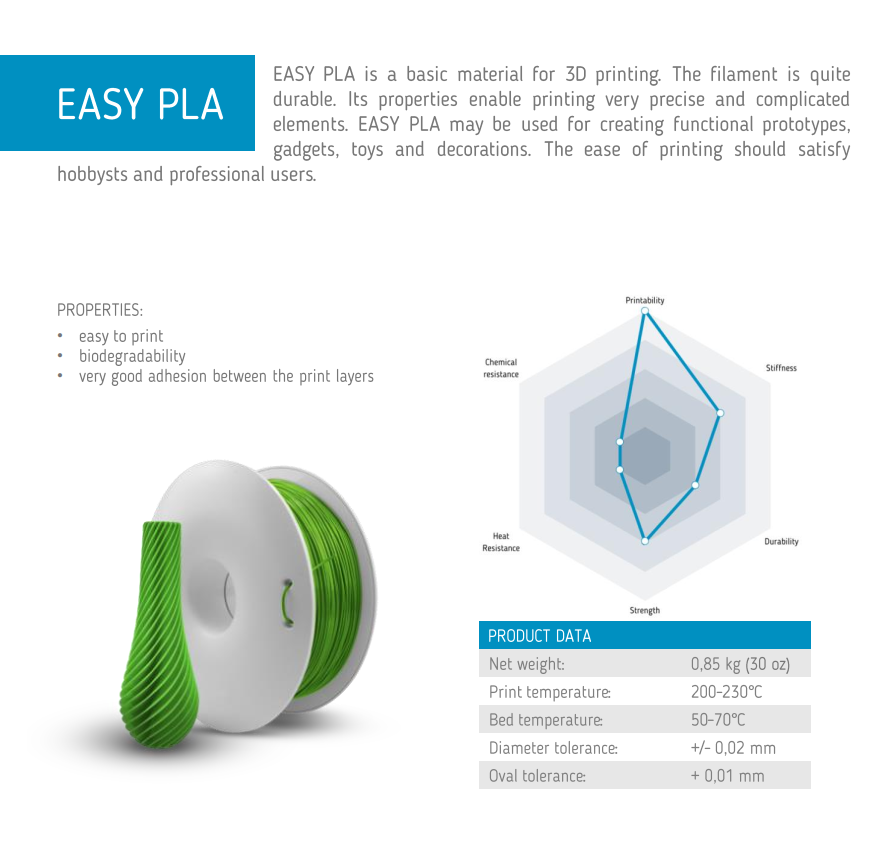

EASY PLA is a basic material for 3D printing. The filament is quite durable. Its properties enable printing very precise and complicated elements.

EASY PLA may be used for creating functional prototypes, gadgets, toys and decorations. The ease of printing should satisfy hobbyist’s and professional users.

Properties:

- Easy to Print.

- Excellent adhesion layers.

- Printing temperature: 200°C — 220°C

- Bed temperature: 50°C — 70°C (when using plates or other means to increase the adhesion, the heating of the bed is not required)

- Diameter tolerance: /- 0.02 mm

- Oval tolerance: 0.01 mm

- Net weight: 85 kg

See download tab for TDS

Looking for a color that is not listed? Feel free to reach out at sales@aero3ds.com

How to print?

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 200-230°C |

| Bed Temperature | 50-70°C |

| Closed Chamber | not required |

| Fan | 75-100% |

| Flow Rate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | glass, masking tape |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 50°C / 4hrs |

Fiberlogy PCTG is an excellent alternative for people looking for a filament with PET-G properties, but with increased impact strength.

Belonging to the same family of polyesters as PET-G, PCTG is characterized by similar strength and ease of printing as its more popular counterpart,

however, thanks to its higher impact resistance, it can be successfully used where ordinary PET-G could not do.

A typical feature of PCTG is its high transparency in the transparent version and resistance to temperatures up to 76°C.

This filament in the Pure TR version can be used for the production of products approved for contact with food.

Parameters:

- High Chemical Resistance.

- BPA Free.

- Easy to Print: Dimensional stability and low shrinkage.

- High Impact Strength: Up to 20 Times greater then PET-G.

- Printing temperature: 250°C - 270°C

- Bed temperature: 90-110°C

- Diameter tolerance: +/- 0.02 mm

- Oval tolerance: +0.01 mm

- Net weight: 75 kg.

See download tab for TDS

Looking for a color that is not listed? Feel free to reach out at sales@aero3ds.com

How to print?

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-270°C |

| Bed Temperature | 90-110°C |

| Closed Chamber | not required |

| Fan | 25-50% |

| Flow Rate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | masking tape, PVA glue, hairspray |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 60°C / 4hrs |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape. |

ABS PLUS is a multi-functional material for desktop 3D printing, recommended especially for prototyping models thanks to its special properties such as increased hardness and reduced process shrinkage. What is more, printing will be easier and faster compared to standard ABS and does not require printing in a closed chamber. It can also be mechanically and chemically processed.

ABS PLUS will find application in the industry, where creating advanced prototypes and end-use parts require increased durability.

Properties:

- Increased Hardness and Durability.

- Higher Impact and abrasion resistance.

- Higher Temperature.

- Printing Temperature: 250-270 °C

- Bed Temperature: 90-110°C

- Diameter Tolerance: +/- 0.02 mm

- Oval Tolerance: +0.01 mm

- Net Weight: 0.85 kg

Additional information:

- Can be chemically smoothed.

- Bed heating is required.

- Possibility of printing in open printers.

See download tab for TDS

Looking for a color that is not listed? Feel free to reach out at sales@aero3ds.com

How to print.

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-270°C |

| Bed Temperature | 90-110°C |

| Closed Chamber | recommended |

| Fan | 0-10% |

| Flow Rate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 60°C / 4hrs |

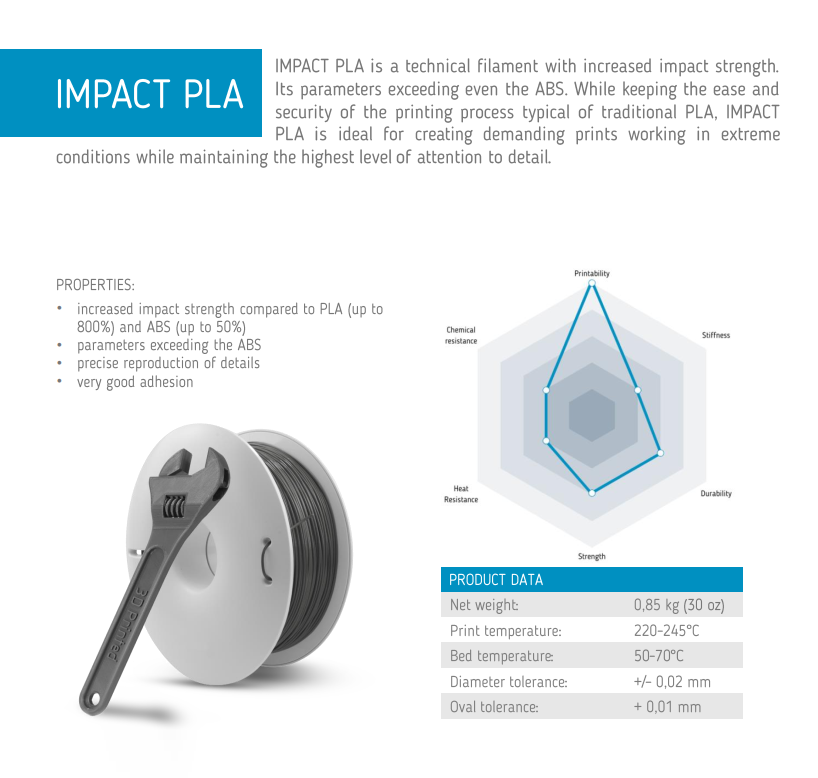

Impact PLA is a technical filament with increased impact strength. Its parameters exceeding even the ABS. While keeping the ease and security of the printing process typical of traditional PLA,

IMPACT PLA is ideal for creating demanding prints working in extreme conditions while maintaining the highest level of attention to detail.

Properties:

- Increased impact strength: compared to PLA - up to 800% and ABS - up to 50%.

- Excellent good layer adhesion.

- Precise reproduction of details.

- Printing temperature: 220- 240°C.

- Bed temperature: 50- 70°C (when using plates or other means to increase the adhesion, the heating of the bed is not required.)

- Diameter tolerance: +/- 0.02 mm.

- Oval tolerance: + 0.01 mm.

- Net weight: 0.85 kg.

See download tab for TDS

Looking for a color that is not listed? Feel free to reach out at sales@aero3ds.com

How to print.

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions

| Nozzle Temperature | 220-245°C |

| Bed Temperature | 50-70°C |

| Closed Chamber | not required |

| Fan | 75-100% |

| Flow Rate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | glass, masking tape |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 50°C / 4hrs |

With PET-G properties, you can make prototypes that are more functional and end-use parts. This is possible thanks to its rigidity, which is better than that of ABS. Thanks to glycol compound, the material is more durable and less susceptible to shrinkage. Chemical resistance to acids, salts, and alkaline substances also widen the spectrum of its applications.

The translucent and non-translucent color options available allow to create amazing prints for different purposes. This material may be used for electronics, prototyping, and decorations.

Properties:

- High durability.

- Low shrinkage.

- Resistant to acids, salts and alkali substances.

- Printing temperature: 230°C — 250°C

- Bed temperature: 90°C

- Diameter tolerance: +/- 0.02 mm

- Oval tolerance: +0.01 mm

- Net weight: 0.85 kg.

See download tab for TDS

Looking for a color that is not listed? Feel free to reach out at sales@aero3ds.com

How to print.

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 230-250°C |

| Bed Temperature | 90°C |

| Closed Chamber | not required |

| Fan | 0-25% |

| Flow Rate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | masking tape |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 3-5 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 60°C / 4h |

| Notes | Due to the strong adhesion to the bed, it is not recommended to print directly on its surface or on glass. This can lead to damage. We recommend using a masking tape. |

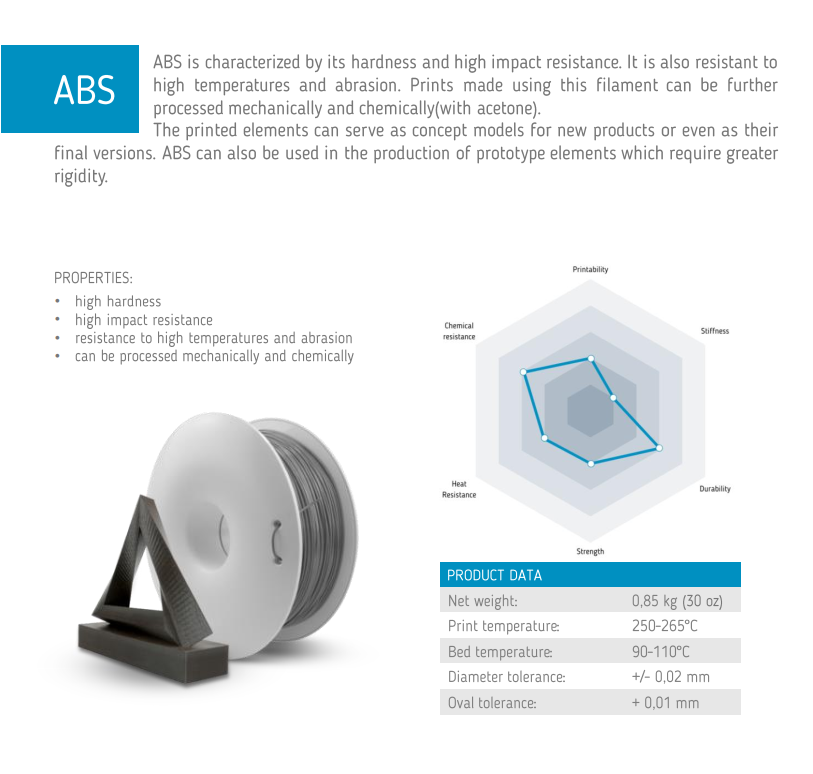

ABS is characterized by its hardness and high impact resistance. It is also resistant to high temperatures and abrasion. Prints made using this filament can be further processed mechanically and chemically (with acetone).

The printed elements can serve as concept models for new products or even as their final versions. ABS can also be used in the production of prototype elements that require greater rigidity.

Properties:

- High Hardness.

- High impact Resistance,

- Resistant to high temperatures and abrasions.

- Printing temperature: 250-265°C

- Bed temperature: 90-110°C

- Diameter tolerance: +/- 0.02 mm

- Oval tolerance: +0.01 mm

- Net weight: 0.85 kg

Additional information:

- Can be chemically smoothed.

- Bed heating is required.

- Chamber heating is recommended.

See download tab for TDS.

Looking for colors that are not listed? Feel free to reach out at sales@aero3ds.com

How to print.

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 250-265°C |

| Bed Temperature | 90-110°C |

| Closed Chamber | recommended |

| Fan | 0-10% |

| Flow Rate | 95-105% |

| Printing Speed | 35-60 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 2-3 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 60°C / 4hrs |

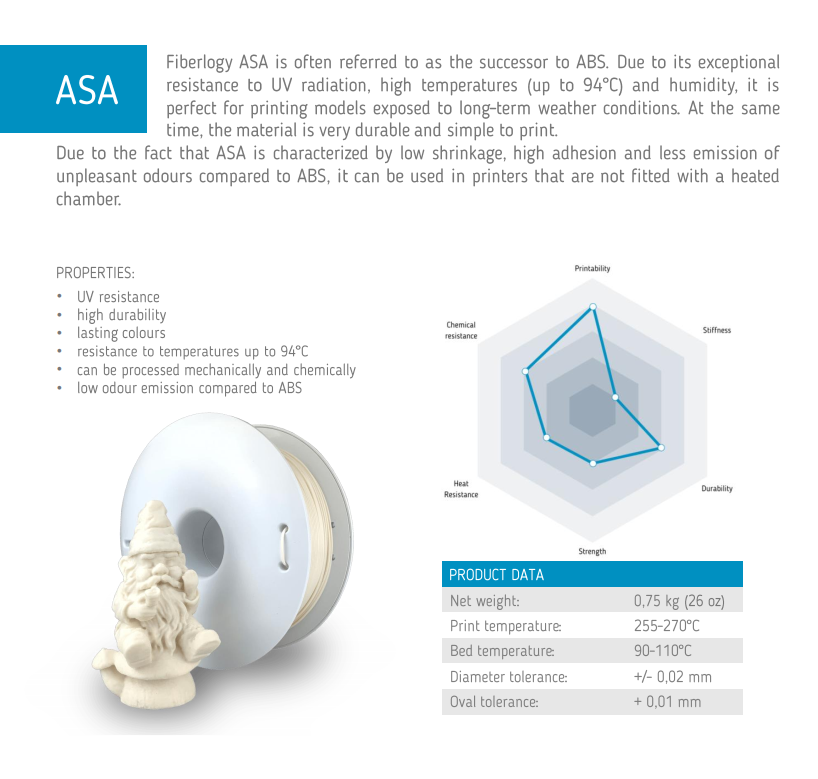

Fiberlogy ASA is often referred to as the successor to ABS. Due to its exceptional resistance to UV radiation, high temperatures (up to 94°C) and humidity, it is perfect for printing models exposed to long-term weather conditions. At the same time, the material is very durable and simple to print.

Because ASA is characterized by low shrinkage, high adhesion and less emission of unpleasant odors compared to ABS, it can be used in printers that are not fitted with a heated chamber.

Properties:

- UV Resistant.

- High Durability

- Colors will not fade over time.

- Can be smoothed chemically.

- Low odor emission during printing.

- Printing temperature: 255°C — 270°C

- Bed temperature: 90 - 110°C

- Diameter tolerance: +/- 0.02 mm

- Oval tolerance: +0.01 mm

- Net weight: 0.75 kg

See download tab for TDS

Looking for colors that are not listed? Feel free to reach out at sales@aero3ds.com

How to print.

The following parameters are only suggested print settings for this material. To ensure the best print quality,

it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 255-270°C |

| Bed Temperature | 90-110°C |

| Closed Chamber | not required |

| Fan | 0-25% |

| Flow Rate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | 1-2 mm |

| Retraction (bowden) | 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Drying Conditions | 80°C / 4h |

| Notes | When printing without a heated chamber, it is recommended to avoid exposing the model to gusts of wind/drafts. |

- 1